Your Credit Estimate

Your Credit Estimate

Your Credit

Your Credit

Your zip code helps us provide you with the most accurate vehicle pricing and vehicle availability.

We estimate your credit score to give you an idea of your monthly payments. To get an accurate payment amount, complete our credit application by clicking the Start Credit Application button below.

start credit application

Continuously Variable Transmission, or “CVT” for short, is sparking quite the debate as of late. Many consumers like continuously variable transmissions because the transition between gears is much smoother, and sometimes undetectable, in comparison to standard automatic transmissions. Other consumers aren’t a fan of that though. Some say continuously variable transmission systems make them feel disconnected to their vehicle, and the ability to feel in control of one’s vehicle is important to many drivers. But maybe there’s another reason some don’t like CVTs; maybe CVTs aren’t as good as automakers say they are?

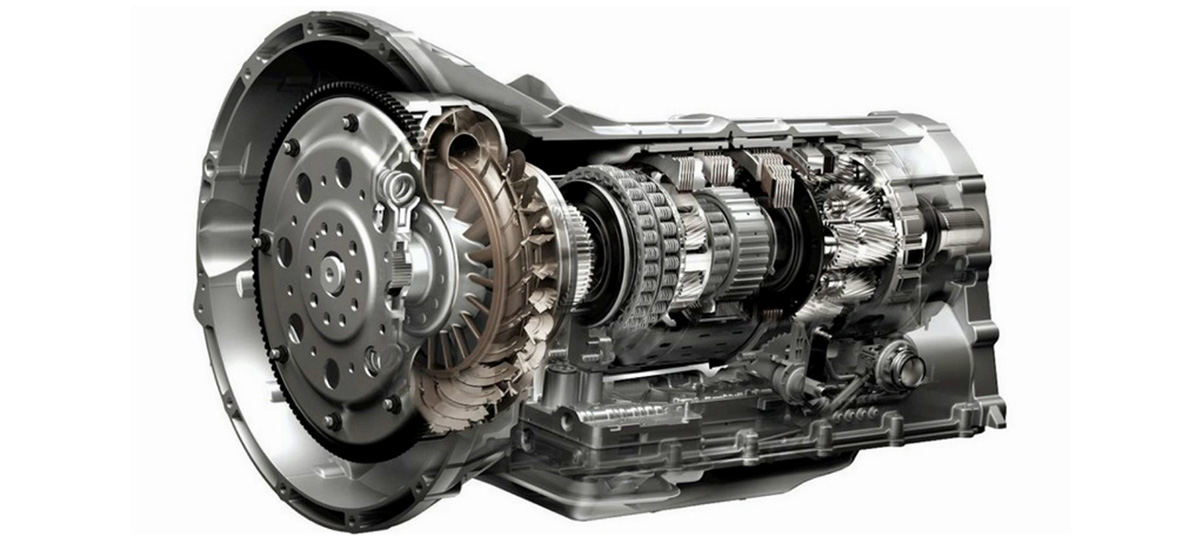

Let’s look at CVT at its core. Continuously Variable Transmission, like an automatic transmission, doesn’t require driver input to change gears. Furthermore, continuously variable transmission can seamlessly change through a continuous range of gear ratios no matter the speed. In contrast, the mechanic transmissions of other standard automatic counterparts are made up of a fixed number of gear ratios for a range of speeds. The former is actually a great design and has been implemented by many automakers.

Take Mitsubishi Motors’ INVECS as an example. “INVECS” is an acronym for “Intelligent & Innovative Vehicle Electronic Control System” and is the brand name for Mitsubishi Motors’ electronic automatic transmission technology. This is how they define it:

“INVECS-III selects automatically the optimal gear ratio based on road and driving conditions. In addition, a CVT that brings out the efficiency from the engine performance is provided. Unlike a conventional automatic transmission, there is no jolt when shifting gears and every time the accelerator is applied, there is enjoyable, smooth acceleration.”

“Efficiency” is a two-parter here. Not only does a CVT make the best use of the engine’s performance in terms of power and speed, but a CVT also helps to improve a vehicle’s fuel efficiency because there is a decrease in lost energy. Take the design of an automatic transmission into mind again. It is made with a fixed number of gear ratios for a range of speeds.

Here’s an example of what happens in an automatic transmission at 0-20 mph. If the driver is applying enough pressure to the gas pedal that will incite the throttle to deliver more power to the engine, just before the automatic transmission switches gears between the 20 mph threshold and the next, it will lose some of the power delivered, much like the energy that is lost when braking. In alternative fuel vehicles, they have regenerative braking to make use of that energy expended when bringing the car to a stop. In internal combustion engine vehicles, there is no use for regenerative braking, and when the car passes that 20 mph threshold, or when it transitions between a high threshold to a low threshold, the energy of the engine is lost whilst the automatic transmission adjusts and switches gears. Ultimately, that also decreases fuel efficiency.

Now, here’s where the debate comes in. Not all applications of CVTs work the same. Some designs have the “rubber band effect”, the result of how some continuously variable transmission systems operate. The general design of a CVT is two pulleys that are held together by a strong steel belt wherein one pulley continuously adjusts to keep the engine rpm at the most efficient level for the driving situation at hand. Therein is where a problem lies. In the case of the rubber band effect, a continuously variable transmission system will cause the engine to hold its revolutions at the highest possible peak until the desired speed is reached.

Because the engine and the CVT have to work in a synchronized manner, and one may be working harder until the desired effect is achieved, there is a higher rate of repeated movements of parts within the system. As we all know, the more engine parts are used repeatedly, the more wear and tear will occur. Some would say this will lead to diminished durability and reliability of a continuously variable transmission in the long-term.

There is hope though. Automakers like Nissan tweak their CVT often. Nissan uses an algorithm to calculate the “wear” placed on the CVT fluid* via miles driven, duty cycles, loads, etc. and how these affect the deterioration rate of the CVT fluid. The same algorithm method is used by many manufacturers with CVT transmission vehicles to determine CVT fluid replacement intervals.

So what does it all come down to? Maintenance. Every difficult problem has a simple solution at the end, and when it comes down to the potential wear-and-tear of continuously variable transmissions, just perform proper maintenance regularly.

Does your car have continuously variable transmission? Do you miss the jolt or prefer its absence? Share your experiences with us on NowCar social media.