Your Credit Estimate

Your Credit Estimate

Your Credit

Your Credit

Your zip code helps us provide you with the most accurate vehicle pricing and vehicle availability.

We estimate your credit score to give you an idea of your monthly payments. To get an accurate payment amount, complete our credit application by clicking the Start Credit Application button below.

start credit application

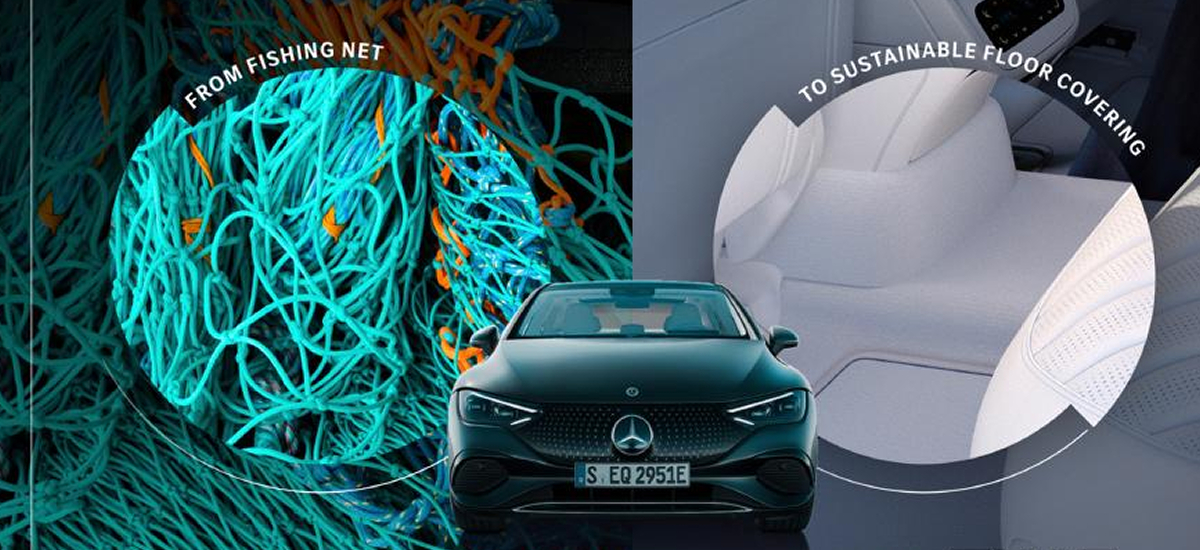

In a word where it seems like every big company is going green, or trying to, many industries have been slow to act. The auto industry is finally, finally making the change. Just about every automaker is making the shift and committing to all new electric vehicles (EVs) to populate their lineups. We talked about several automakers earlier, with just about everyone sharing a new business plan for 2030 and the goals they have in electrified vehicles, among other things. Mercedes-Benz is another company, having just released a PR on their future of sustainability. Like the image seen above, changing old and used fishnets into vehicle cabin floor covers, is just one of the many things Mercedes-Benz is doing to reach a fully electric, emission-free future.

"Sustainability is the foundation of all Mercedes-Benz research and development activities. Our goal is to be the technology leader in environmental engineering by achieving more with less. To this end, we are accelerating our innovation speed and bringing new, sustainable technologies into series production as quickly as possible - for example from the VISION EQXX. After only a few months, we are integrating the first sustainable material from our technology program into ongoing series production. As pilot series, the EQS and EQE will be equipped with cable ducts made from UBQ™, a plastic substitute material derived from household waste," - Markus Schäfer, Member of the Board of Management of Mercedes-Benz Group AG, Chief Technology Officer

As mentioned above, Mercedes-Benz is utilizing a material called UBQ™ made from the conversion of mixed household waste that is usually difficult to recycle, such as food residues, mixed plastics, cardboard, and baby diapers, and instead, thrown out with the rest of the garbage to end up in a landfill. With all of our advancements, those places still exist, believe it or not. If you’ve ever taken a long drive across Florida, you’ve smelled it, and it is rancid. Instead, these common trash items will instead be turned into future vehicle components, such as underbody panels, wheel arch linings, and engine compartment covers currently being tested. That’s just the beginning.

Sustainable Luxury

Designing for the environment, Mercedes-Benz is working in a lot of lanes to get this done. For instance, who doesn’t like a vehicle interior with leather? The automaker will be working towards sustainably processed leather, made with materials with a high recycled content and materials that will be used in the design of future models, such as the ongoing EQS and EQE series. The car body is made from CO2-reduced steel, and Mercedes-Benz is taking everything from livestock breeding to the tanning process in the future of their production. Sure, animals are killed for leather, but the company does want to make sure its suppliers comply with the "5 Freedoms Of Animal Welfare" of the Animal Welfare Committee in livestock breeding. The automaker also makes sure the supply chain is free from any form of illegal deforestation.

The tanning process is also changing, now using vegetable or alternative sustainable tanning agents free of chromium, and mostly natural, like dried coffee bean husks, chestnuts, etc. Following the Gold Standard of the 'Leather Working Group', all leather in Mercedes-Benz products needs to be certified that they meet important environmental aspects such as reducing the use of water, energy and chemicals in the tanning process. For consumers who don’t like the idea of killing an animal for luxury and comfort, Mercedes-Benz is also working on sustainable leather alternatives. These include leather made from renewable raw materials, such as powdered cactus fibers, fungal mycelia, and the highest possible recycled content from renewable materials instead of harmful things, like petroleum-based resources.

Conserving Resources through Innovative Recycling Materials

As said above, Mercedes-Bens is working on new materials that it can use in the production and design of its future models. In the interior, aside from leather, Mercedes-Benz offers various high-quality upholstery fabrics made from up to 100-percent recycled PET bottles. The floor coverings mentioned above are made from nylon yarn that comes from recycled carpets as well as recycled fishing nets. This alone saves over 6.5 tons of CO2 when compared to the production of new material over recycled material. Mercedes is even focused on the reduction of polluting plastics by working with renewable raw material.

Sustainable Materials of the Future

Instead of the normal harmful plastic, Mercedes-Benz obtains high-performance plastic made from chemical recycling, where used tires and other plastic waste are broken down into their chemical components, able to be used to make something new. That’s actually not a bad idea – why isn’t this done on a global scale? Probably it’s a catch-22. Sure, it makes better products and resources, but some have been found to be lethal to human health, but honestly, who is going around ingesting styrene, formaldehyde, ethylene, epoxy resins of BPA, or vinyl chloride? The renewable materials Mercedes-benz will be producing will be used for things like door handles. Seat cushions are being made from partially CO2 based foam, trapping the CO2 instead of releasing it back into the atmosphere. Another renewable material is bamboo fibers, used for carpeting and other components of the interior of a vehicle.

CO2 Reduction in Body-in-White and Body

Like many of the materials discussed, Mercedes-Benz is paying a lot of attention to materials that are CO2-intensive in production, such as steel and aluminum. Pursuing the goal of decarbonizing the steel supply chain, Mercedes-Benz has its own business plan, Ambition 2039, to reduce if not fully avoid CO2 emissions, starting with CO2-reduced flat steel from Salzgitter Flachstahl GmbH, made from 100-percent scrap materials. More than 60-percent of all Mercedes-Benz A-class models are made with CO2-reduced low-alloyed grades of material. This makes the automaker the first vehicle manufacturer to introduce this resource-conserving, CO2- reduced sheet metal into series production.

By 2025, Mercedes-Bens is aiming for CO2-free steel, manufacturing done with hydrogen instead of coking coal (contains more carbon than thermal coal), a huge and essential for the steel produced today. So, that will surely be something to see. Either way, Mercedes-Benz is committed to this, and with another first, is the only car manufacturer to take an equity stake in the Swedish start-up H2 Green Steel (H2GS). Plans are for fossil-free steel with iron made with hydrogen are already in motion. Heck, the upcoming Mercedes-AMG SL, will have structural castings made of die-cast alloys made from up to 100 % recycled aluminum scrap. Will the integrity and safety be the same? We’ll wait on the tests from the Insurance Institute for Highway Safety (IIHS) to weigh in on that one.

Mercedes-Benz has joined the many automakers with a long-term business plan, but instead of talk about EVs, it’s about a sustainable future. Also good. You can keep up with everything Mercedes-Benz and other automakers are working on when you follow us on NowCar social media.